Dynos - What to know

Intro

Dynamometers are a tool at the heart of the tuning and automotive industry. Being able to measure the power an engine produces is the only way to get a good indication of how much difference your new turbo, injectors or remap has really made. The power figures and graphs produced are the source of much speculation, competition and controversy in the industry. This is made worse by a general culture of misunderstanding by the public, which can be taken advantage of by those in the tuning business.

What is a dyno

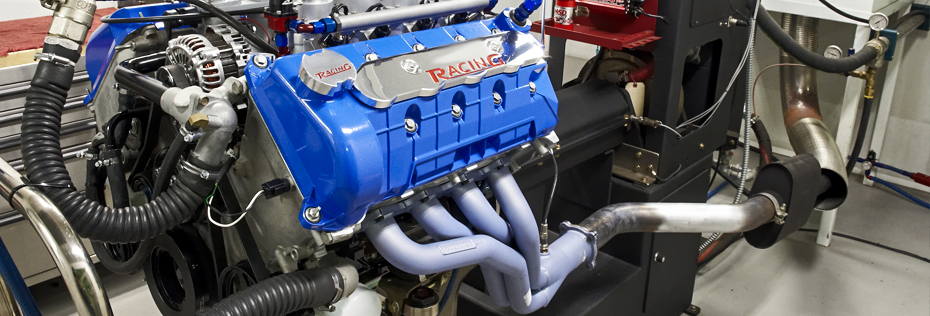

A dynamometer is a tool designed to measure the performance of an engine. These can come in several types - manufacturers like Volkswagen for instance will likely use Engine dynamometers, which run the engine directly on a stand without it being installed in a vehicle. Generally the type of dyno seen in the tuning industry is called a Chassis Dynamometer - this measures the power of a vehicle, usually by means of rollers turned by the wheels, or in some cases units attached to the vehicle hubs.

Engine Dyno

Hub Dyno

Chassis Dyno

More than just a power figure

While dynos are best known for producing a peak power and torque figure for the vehicle being tested, the real value of a dyno is as a test-bed and tuning tool. On a dyno it is possible to simulate almost all types of driving while eliminating many of the variables and risk you would find on the road - it isn't practical, for instance, to check whether boost will control at the top of 6th gear in a car that can do 150mph, but on a dyno you can perform a test like this easily. This means that if the customer takes their car to the autobahn, the turbo doesn't blow up due to overboost.

Most commonly people associate dynos with a full throttle sweep test - usually referred to as a ‘dyno pull’ - however this is only a small part of what a dyno can actually do. Dynos are capable of holding the engine at any speed, performing sweep tests at different speeds and ramp rates or holding the engine at a constant torque value. Not only that, but it can do an identical test over and over again - this means a skilled operator can be sure it is the changes in the engine mapping which are causing the differences in performance, and not changes in the test itself. Its this which makes a dyno such a powerful tool, as long as all conditions are kept consistent (see below)

Most dynos also have the ability to capture much more data than just power and torque - the operator can hook up sensors for boost pressure, Air to Fuel Ratio, Exhaust Gas Temperature, and many more if required.

Dyno Tune vs Dyno Run

It is important to understand the difference between a true dyno tuned remap, and a remap with before and after dyno pulls. Before and after means just that - the car does a couple of dyno pulls, the remapped file is flashed onto the car and the car does another couple of dyno pulls to illustrate the improvements. All the dyno is used for in this case is to measure the power before and after.

A true dyno tuned custom remap involves using all of the functionality of the dyno to produce the best file possible. The car will be strapped on the dyno and run up stock to check power whilst logging data such as boost pressure, AFR and temperatures. The map will then be tweaked several times between pulls until the best possible performance in terms of power, torque and smoke level within the safe limits of the engine and the desired smoke level.

The Dyno Cell

Another area of real importance is the dyno cell itself. The temperature and airflow conditions can make a huge difference to the performance of the vehicle - this is why when accurate figures are required, manufacturers use Climatically Controlled test cells, which make sure the temperature, pressure and humidity inside the cell is absolutely constant, often with very complicated fan systems to simulate the exact airflow for the speed of driving being simulated. Unfortunately, test cells such as this cost tens of millions of pounds to build, and eye watering amounts to maintain. They also take up huge amounts of space and usually require several operators to run a test - this means they aren’t practical in the tuning industry.

The most basic dyno setups will have a dyno unit sitting on the floor in a room or unit, with floor standing fans positioned in front of the vehicle by the operator to provide some cooling. Usually these fans have only one setting. Many setups like this also have no dedicated fresh air ventilation. This means as the vehicle is run, the temperature inside the building can increase. Sometimes the fans are too small to provide adequate cooling (1 to 2kW are normal), and sometimes they are so large and positioned so close the cooling is unrealistically high and concentrated, essentially increasing the pressure into the engine, which again inflates figures.

Better systems, such as our cell here at Darkside, have a ducted industrial 50kW fan system which maintains a constant slightly negative (3-6mb) pressure in the cell. This means that not only is the pressure constant, but also all the air in the cell is constantly replaced, so there is no build up of gases, which can lower power figures and are dangerous to the operator!

Consistent conditions will yield consistent results allowing the changes made from run to run to be analysed accurately without the need to apply extra error margins.

Dodgy Figures

The main issue with dyno figures, and in particular quoted peak power and torque, is that they are subject to significant variation based on an almost infinite number of factors. This means that it is impossible to really compare figures to each other.

Business and reputation in the tuning industry can rely heavily on dyno figures, and generally when it suits companies they will state their dyno figures as fact - even though anyone with real dyno knowledge knows the figures aren’t comparable anyway.

Below is a small list of things which can have an effect on a dyno result:

Dyno type/brand

Dyno settings

Air temperature

Cooling fan speeds

Cooling fan locations

Tyre type

Tyre pressure

Tyre temperature

Tyre age

Tension of dyno straps

Even things such as how sharply the operator presses the throttle can have a surprising effect.

Some examples of how these factors can affect power readings are shown below

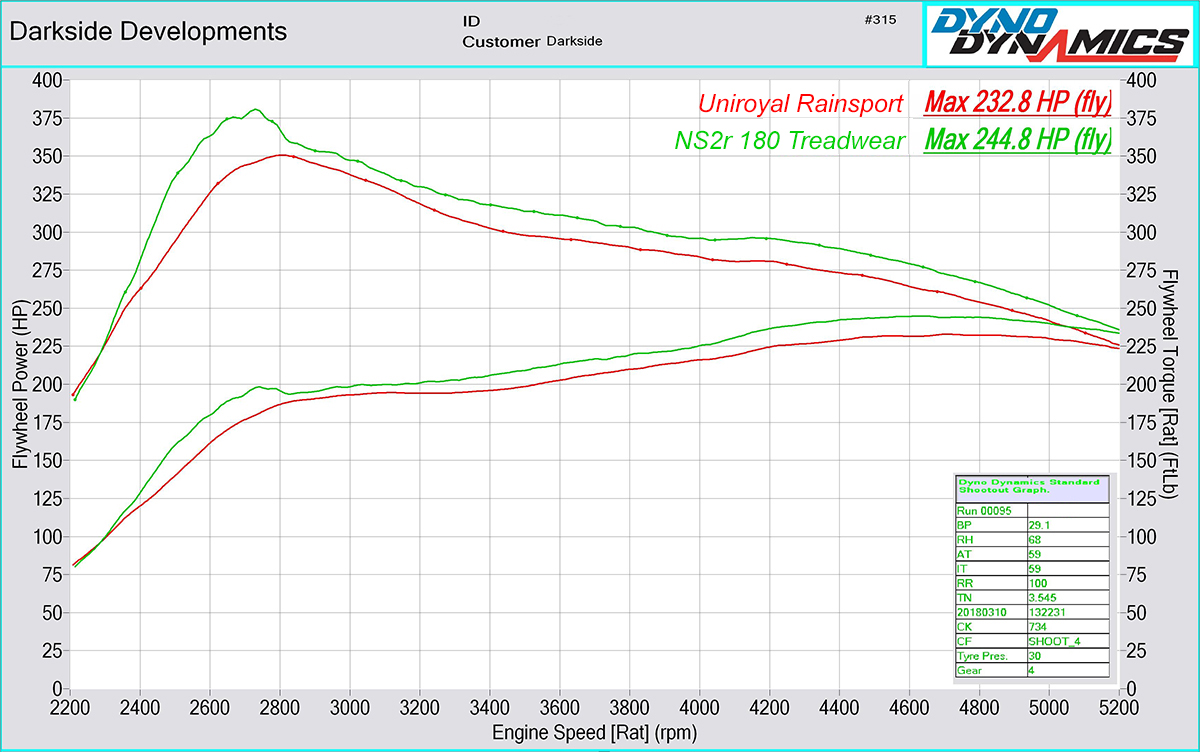

Tyre Type

Our Ibiza Track car has spent a lot of time on the dyno. Recently before a trackday we strapped it on to check the engine was healthy and we were down on power by some 15bhp - the only difference being it was fitted with our wet track tyres, a brand new set of Uniroyal Rainsports. These felt noticeably soft and sticky to the touch after each dyno pull. Refitting our Nankang NS2R dry weather tyres, which are a much harder (180) compound when warm, restored all the power.

We later tested with Toyo R888R 100 compound tyres and we lost even more power, down to 220hp so the difference can be significant. Drag specific tyres should never be run on a chassis dyno.

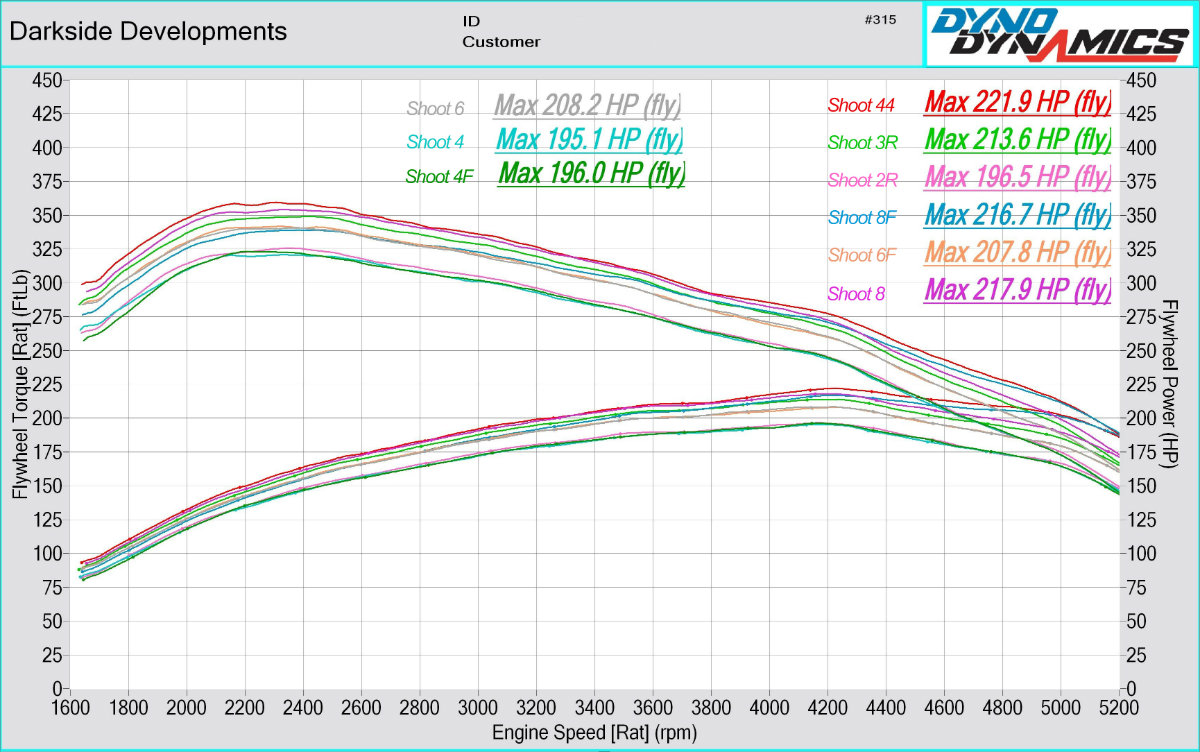

Dyno Settings - Shootout Modes

Our DynoDynamics system uses something called ‘Shootout Mode’. This is a mode with many variables pre set to specific values to ensure consistency between any other DynoDynamics system, wherever it is in the world.The number is supposed to represent the number of cylinders the vehicle has, so in most cases, we use Shoot4F and Shoot6F

The above graph was the same vehicle, 1 run after another, with no changes made to anything, other than the Shootout Mode and there is a significant difference in both power and torque.

This is the main way that some unscrupulous companies inflate their figures (or deflate others when a competitors car is tested)

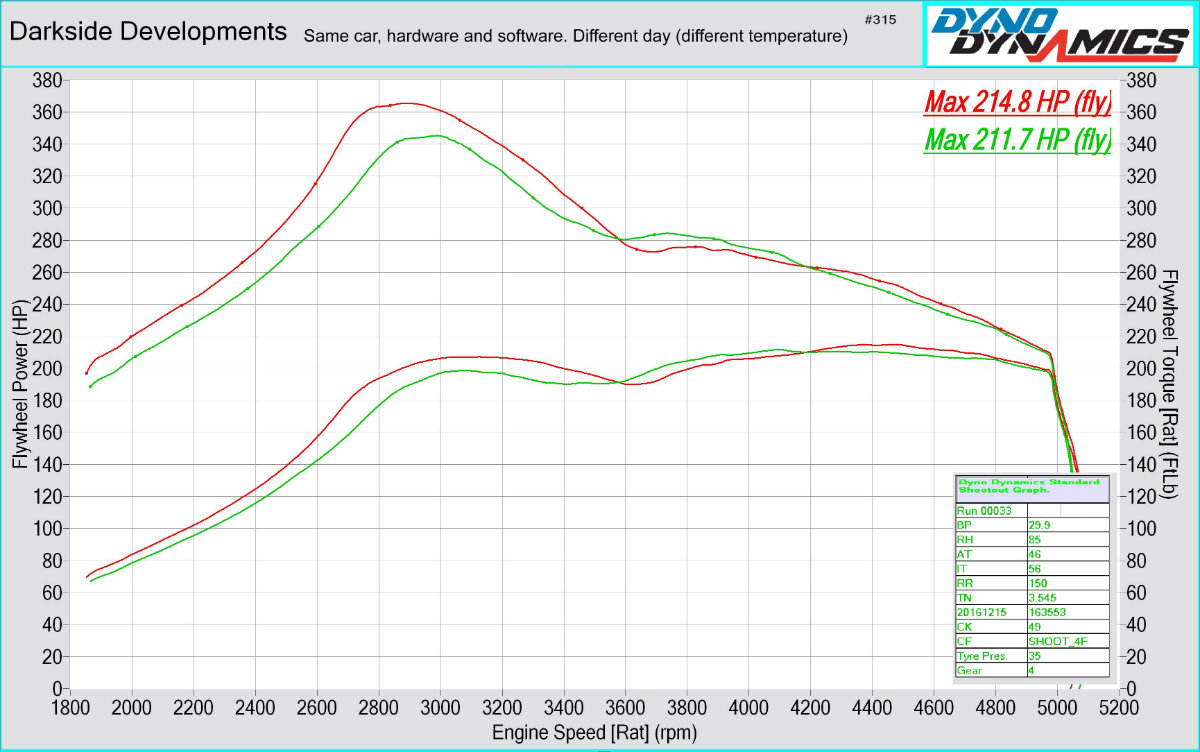

Air Temperature

Low ambient air temperature generally makes cars more powerful. Cool air is more dense, allowing the engine to generate more power and cold ambient air also makes the intercooler work far more efficiently, further increasing power.

Our dyno has an ambient air temperature sensor and therefore corrects for this but you can still end up with different figures, see below for a run showing the same car run one cool evening and then run again in the morning when the temperature was higher:

The placement of the Inlet Temperature (IT) probe has a dramatic effect with some operators choosing to have the probe very close to the engine, thus increasing that temperature differential from the Ambient Temperature sensor (AT) and increasing the compensation value. We tend to leave the sensor tied up in the same position as not to add another variable to our results.

Dyno Brands

There are many brands and types of dynos, all of which have slightly different settings and testing procedures. Some of these are chosen by the operator. Some Dynos are known to read much higher than others, which means the only way to truly test the output of a vehicle vs another, is to run them on the same dyno under the same conditions.

In the UK we usually quote power and torque at the engine flywheel just like all manufacturers - a chassis dyno however measures the torque and power at the wheels, which is always a lower figure as some energy is lost in the driveline. This loss is different for different vehicles. The flywheel power quoted is therefore a calculated value - it is not directly measured. Some dynos will simply estimate this loss based on settings inputted by the operator - our Dyno Dynamics dyno operates in this way. Other dynos perform a ‘coast down’ measurement to try and measure the driveline loss. In theory coast down should provide a more accurate figure for more vehicles, but in reality both methods have their own issues.

Run length can affect the output of an engine, especially a turbocharged one. A short run would not always load up the engine enough to make full boost. Too long will also make what on the road could be a very laggy turbo appear to spool very well.

Inertia vs braked Dyno's is a very long discussion but from our experience, Braked is always better for the reasons mentioned above, we would never purchase or test on an Inertia dyno.

In the future we plan to purchase a new AWD dyno, the choices are vast but when taking everything into account there are not many choices that come without compromise.

Summary

- If a stock car reads higher bhp before a remap it is usually because the dyno is reading higher not because the car is 'healthy'. Figures will usually be inflated before and after.

Our dyno reads 140bhp for PD140 cars and will normally see around 180bhp when tuned.

Other dynos may read 150-160bhp for PD140 but claim the remap will produce 190-200bhp when tuned. Usually these companies wont show the stock figure. - DSG and Haldex cars will read lower on our dyno as these factors effect the 'calculated value'

- Some cars never make stock power. We have run several Bi-TDI T5 Transporters '180bhp' models and all have produced around 15-20bhp less than the quoted manufactures figures and always short of the 220bhp some tuners claim.

- If you want to track the progress of any modification's made to your car, use the same dyno each time and control as many variables as possible to ensure accuracy.

Recent Posts

-

Oulton Park - ClubEnduro - 750MC - 21st September 2024

After a great result at Silverstone, we had a 5 week break before we out again, this time for a 100 …07 10 2024 -

Silverstone International - Roadsports & ClubEnduro - 750MC - 17th & 18th August 2024

After the disaster at Cadwell, it was time for another double header at Silverstone on the Internati …19 09 2024 -

Cadwell - Roadsports - 750MC - 21st July 2024

After a long day at Oulton for TimeAttack, we had to pack up and drive across to Cadwell. Straight t …14 08 2024