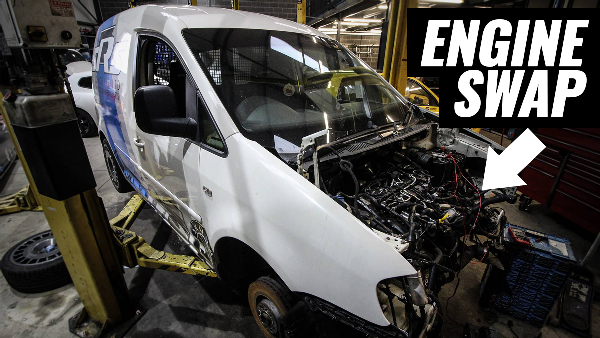

4WD and Cage - SRS 2.0 CR TDI DQ500 4-Motion Caddy Build - Part 2

So the front wheels are sorted, but what about getting the power to the back? Obviously there is a rear axle setup available from the Caddy 4-Motion, but this is a beam and uses the leaf springs. OK for doing some occasional green laning (for those of you who are unaware - https://www.glass-uk.org/), but not so good for hitting the track hard!

A 4-Motion Caddy with multi link rear suspension is nothing new, with VW Motorsport / Racing Line running one in the VW Cup for quite a few years (See Here), as well as a number of conversions done by private individuals both in the UK and Europe.

All had different ways of doing it, but we settled on a method that requires minimal cutting of the Caddy Chassis, minimal custom parts and looks neater overall. We have the capabilities with our Fabrication team to get the job done, but not the time to do it, so we enlisted the help of our local drifters Slide Motorsport who were keen to work with us to get the idea from Stef’s head to reality. It is basically the rear chassis of an A3 Quattro, grafted to the underside on the van, so there was no need to cut the original floor meaning from the inside it wouldn't look unlike any other Caddy, except for the rear suspension strut tubs. These were only needed as Stef wanted an upright coilover fitting rather than the separate damper and spring as found on the A3 as standard.

After this was done the original Caddy cross bracing was fitted back in to give the floor some strength. Once we get this all seam sealed and under sealed, we think it will look like it came from the factory like this, then we can move on to fitting the shiny parts. While all this was getting done, it would have been rude not to weld in a custom roll cage, with the door bars fitting as low as possible so it would still be easy to get in and out, since the plan is to use this daily. We also requested the rear strut brace be removable so we can easily take it out when we're off to collect parts in it. Some progress photos are below, and I will let Stef at SRS take over for the rest of the build, since our involvement extends to the drivetrain only :-)

Other Blogs...

Recent Posts

-

Croft - Roadsports & ClubEnduro - 750MC - 19th - 21st April 2024

2024, a new year and a new racing season for us! For me it also time for a new race car. The Golf ha …12 05 2024 -

Silverstone GP - ClubEnduro - 750MC - 29th October 2023

An unusual calendar for 2023 meant that round 7, the final round of the season for the 750MC Club En …23 11 2023 -

750MC Birkett Relay - Silverstone GP - 28th October 2023

With a hectic season of racing almost to a close, we were back at Silverstone for the 750 Motor Club …15 11 2023