PD Engine Hardware Tweaks

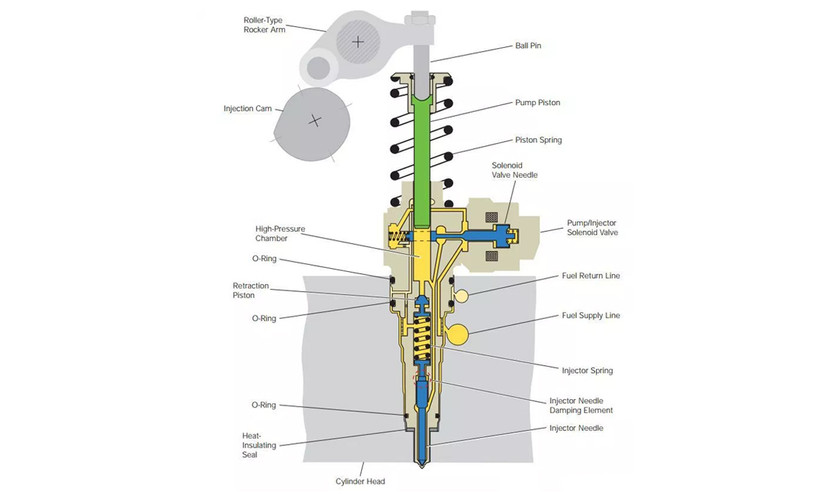

In 1999, Volkswagen introduced what would become one of the most well known engine designs of modern times - the Pumpe Duse (PD) diesel engine. In a departure from many of its rivals, the PD used unit injectors rather than a common rail system, despite most manufacturers thinking that common rail was the better design. Volkswagen proved them wrong for many years, with these strong, reliable, powerful and economical engines being a huge part of what made diesel cars popular. Their 2000 BAR peak injection pressure wasn’t matched by many common rails until 10 years later, and even nowadays the fuel economy, tunability and strength of these engines still makes them a great choice for any project.

The four cylinder PD engines came in 3 distinct generations - 1.9 and 2.0 8-valve Single Cam Engines, 2.0 16 valve Twin Cam engines, and late model 2.0 16 valve engines with Piezo injectors (often known as PPD engines - Piezo Pumpe Duse). In addition there is the small 3 cylinder 1.4 TDI PD engine, a 2.5L 5 Cylinder fitted to VW Transporter and Touareg, and the monstrous V10 TDI known mainly for powering top of the range VW Touaregs. There are a few other minor variants but we will keep this simple. Underpinning all these engines is the same unit injector PD technology.

This blog is going to take a quick look at two hardware adjustments that can be made on any PD engine to optimise performance - Cam Timing, and Actuator Rod Length. These adjustments differ slightly depending on the model, but are essentially achieving the same goal on any PD engine. At Darkside we check and adjust these settings on every vehicle we tune.

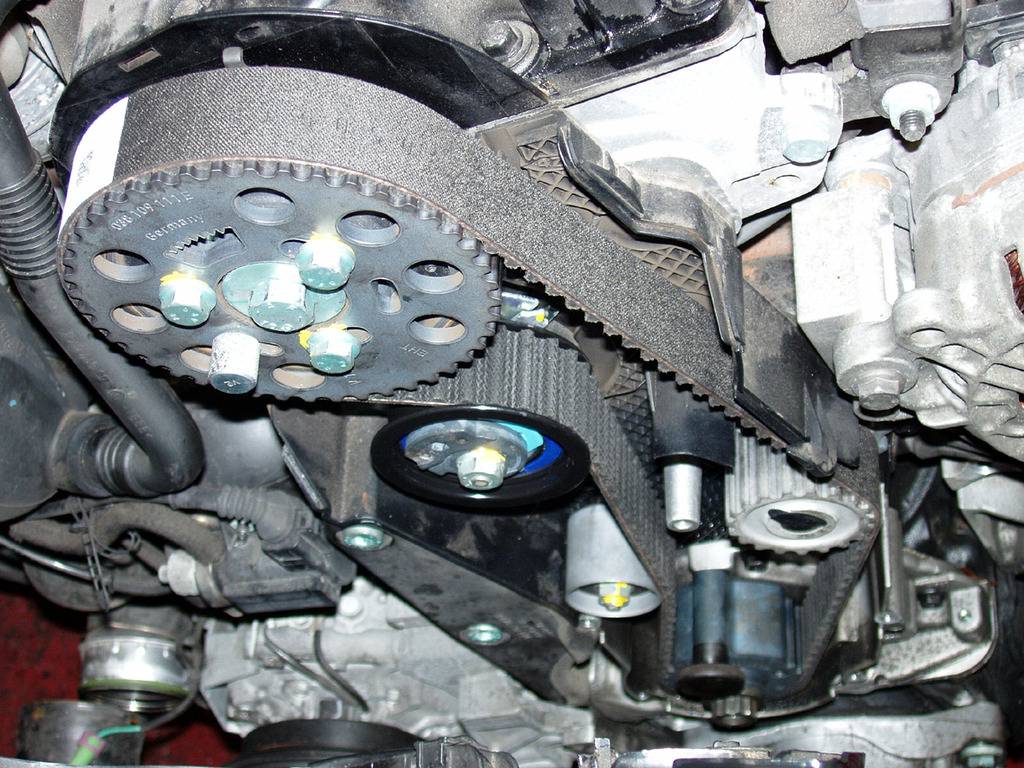

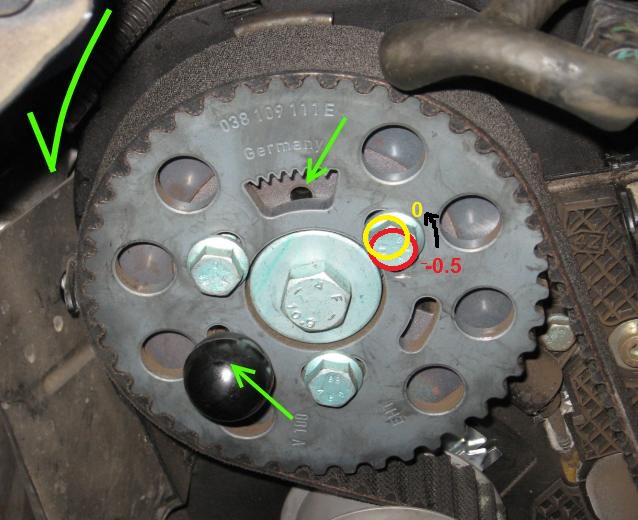

Cam timing is the position of the camshaft relative to the crankshaft - it is important on all cars, and is usually set when the cambelt is fitted or replaced, by locking the cams in place and lining up the crankshaft with timing marks. This ensures the cambelt is sitting on the correct teeth on each pulley and therefore the engine is in sync with itself or ‘correctly timed’. On a PD engine, the timing can be further fine tuned using the adjustable cam pulleys located on the end of the cams

Using diagnostic software it is possible to check the synchronisation of the crank and camshaft. Of the hundreds of PD vehicles we have tuned, in 90% of cases the timing is not adjusted correctly and we are able to make a dyno measurable improvement to power through timing adjustment alone. When the cam timing is out by several degrees, usually the car will idle rough and may struggle to start, along with reduced performance. When the cam timing is only slightly out, symptoms may not be obvious to customers, but can still affect fuel economy and make a measurable difference on the dyno.

Uniquely to the PD engine, the injectors are ‘pumped’ by the camshaft. This means that the timing of the cams doesn’t only affect valve openings, but also the fuelling of the engine. It is this which makes the cam timing so critical to performance - if it is incorrectly adjusted, the engine will essentially operate with incorrect fuel pressure, which can result in slightly less or too much fuel being injected, due to the fact that this mechanically produced pressure is not measure or compensated for by the ECU.

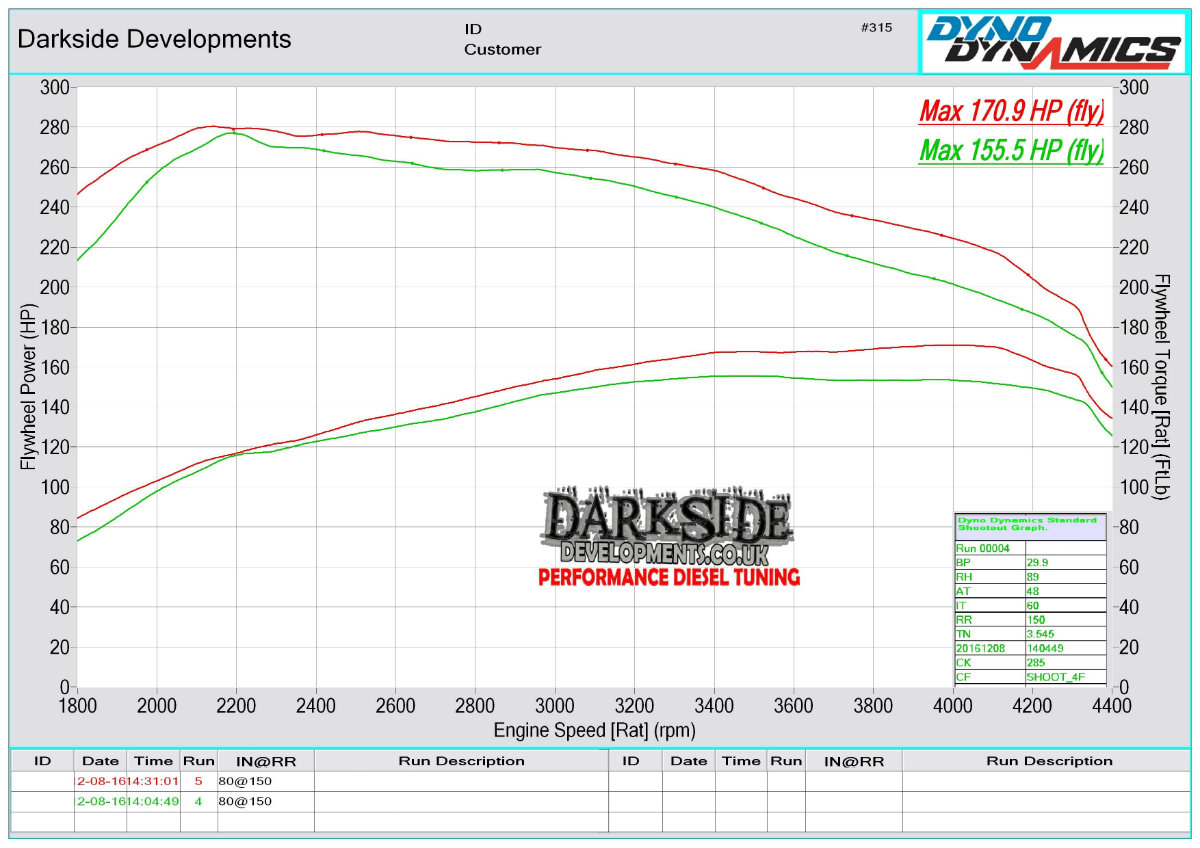

In tuned vehicles, it is possible to adjust the cam timing away from the factory settings in order to gain more power. The adjustment will vary depending on the vehicle, state of tune and desired performance, we determine the exact value on the Dyno. We always fine tune the setting on our dyno to ensure optimal performance.

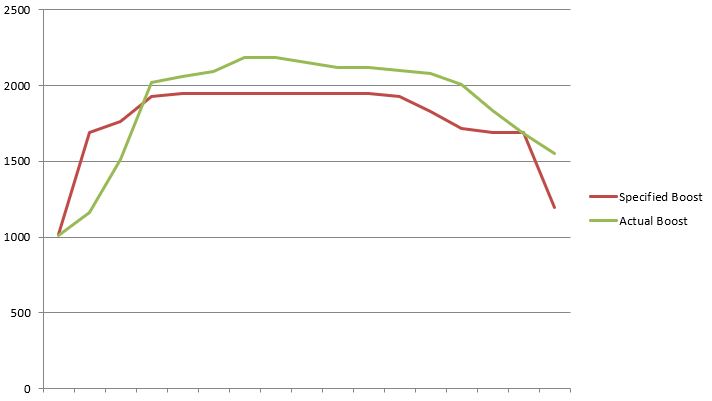

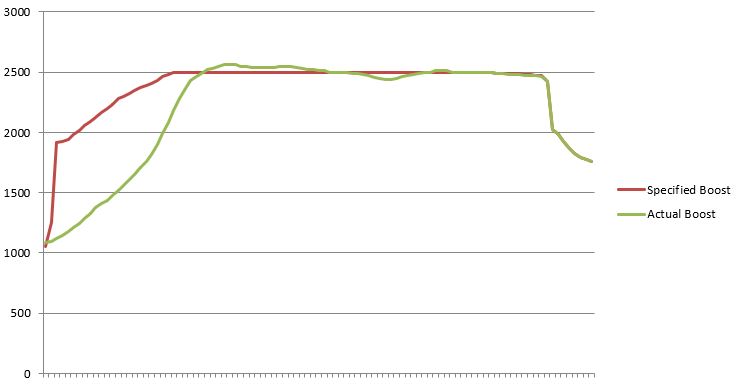

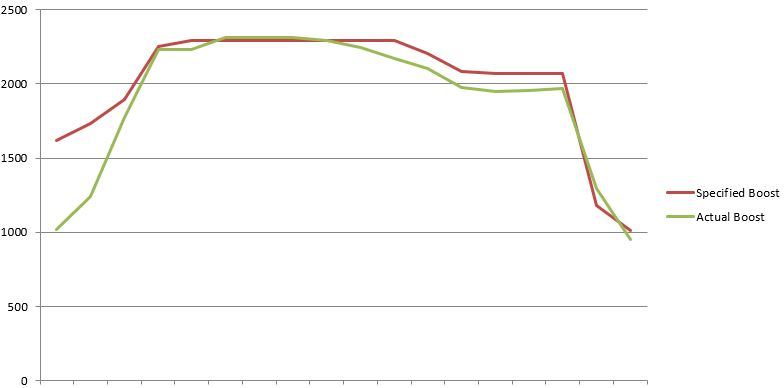

Below is an example of a standard PPD170 engine, before and after timing adjustment. On these engines a gain of 10bhp or more from correcting the timing is typical.

Its worth noting that the 16v PD engines have the cam position sensor located on the front Intake camshaft but the rear exhaust cam is the one driving the Injectors and this cam has no physical sensor to measure its position. Again this is found to be almost always out of adjustment and the rectification is fairly simple. Set the front cam to Zero in VCDS and pin it. Then set the rear cam until the pin will drop in perfectly. Just ensure that the front cam to crank position is not reading zero due to being so far out of adjustment the sensor cannot read at all!

The second adjustment, which is not as specific to the PD engine as the first, is the turbocharger actuator rod length. PD engines are fitted with Variable Nozzle Turbochargers (VNTs) - these turbos are capable of producing much better performance across the rev range than a normal wastegate controlled turbo. They achieve this through a set of vanes which can open and close - they close to accelerate flow past the turbine and create more boost at lower engine speeds, and they open to allow more flow and control boost at higher engine speeds. The movement of the vanes is controlled by the ECU, but older ECU models are less sophisticated and therefore the physical mechanical setup of the rod is critical to ensure good performance. A poor setup is a common cause of turbocharger failures.

The vanes are moved using a vacuum actuator, via a linkage which includes an adjustable length rod. The Vacuum system is another Achilles heel of many diesel engines, and N75 Valve is used to regulate the vacuum to the turbo actuator, so even a tiny leak will cause underboost and eventually the VNT mechanism may be stuck and a new turbo required. A tiny hole in a pipe or more commonly a worn outlet on the vacuum pump are the main issues causing poor performance of the VNT mechanism.

The length of this rod is critical to turbocharger and therefore engine performance.

A shorter actuator rod means that at all times the vanes are more closed at rest. This normally makes the turbo spool faster, but also reduces the ability of the turbo to control boost and flow exhaust gas at high RPM. If the turbocharger rod is too short, usually boost will spike at low RPM and creep at high RPM and the restriction created by the closed vanes can limit power.

A longer actuator rod means the vanes are more open. This makes the turbo spool slower, but allows it to flow more at high RPM and control boost more easily. An overly long actuator rod will result in a lazy response and slow spool, and often underboost at the top end, losing power.

A correctly adjusted actuator provides the best of both worlds - optimum spool with no spikes and plenty of flow at high RPM to avoid boost creep and achieve maximum power. Like the Cam Timing, the correct setting is specific to the exact hardware setup on the vehicle. The exact length is determined by logging the car in different states and adjusting as necessary.

With both these adjustments, our extensive experience means we can often make a good first guess at how to set the hardware, but especially for unusual hardware setups or highly tuned vehicles, it is through testing, numerous dyno pulls and data logging that we arrive at the final setting.

We hope this has given a little insight into the importance of hardware adjustment when tuning PD engines. Remember, at Darkside we check and adjust both Timing and the Actuator on all vehicles when we perform a Custom Remap - the best remap in the world cannot make up for poorly adjusted hardware!

Recent Posts

-

Failed High-Pressure Fuel Pump (HPFP) - Checklist: What to Do After a Pump Failure

We commonly see failed High-Pressure Fuel Pump (HPFP) on modern Common Rail Diesel Engines resulting …10 12 2025 -

John O’Groats to Land’s End on One Tank! 400bhp 335d

This is the story of one customer’s idea to travel the entire length of the UK on just one tank of f …20 10 2025 -

Oulton Park International - ClubEnduro - 750MC - 20th September 2025

After the disaster of Silverstone for the 750MC RoadSports, we had a few weeks to gather ourselves r …18 10 2025